Want to be notified of news like this? Become an ECD Insider and be in the know first.

ECD to Showcase New M.O.L.E.® EV6 Features, Preview Expanding Touchscreen Thermal Profiling Portfolio at productronica 2023

M.O.L.E.® EV6, the Market’s Only Touchscreen Thermal Profiler, Adds Bluetooth® Capability and Welcomes New Additions to the Portfolio

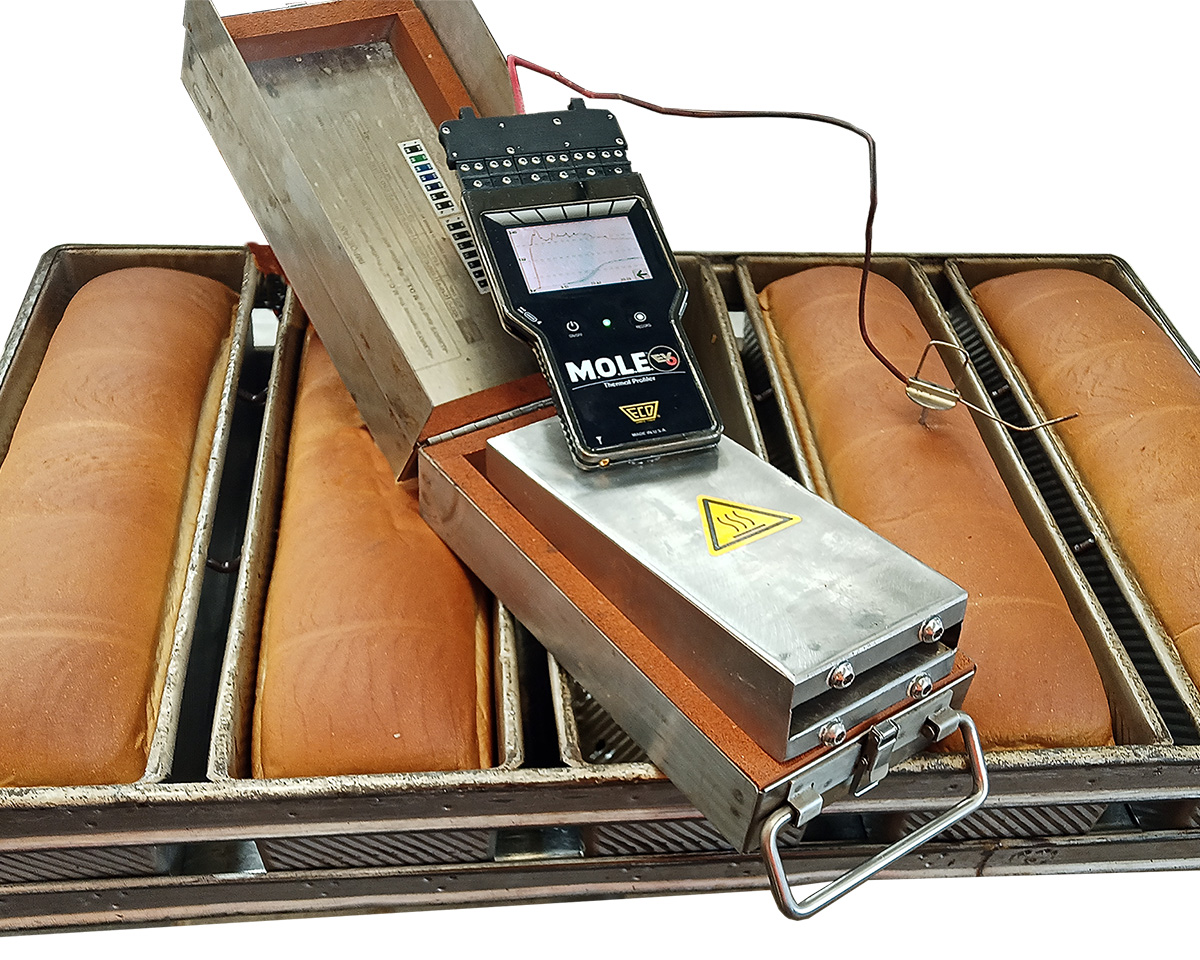

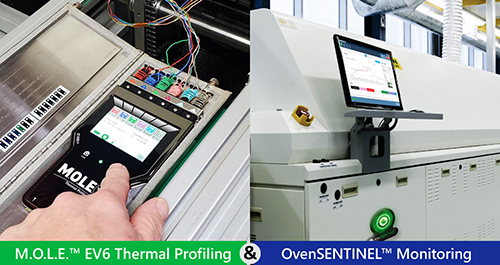

October 16, 2023 – Since the launch of the first-ever touch control thermal profiler, M.O.L.E.® EV6, ECD’s new tool has enjoyed wide industry uptake and has recently integrated additional features like Bluetooth® wireless connectivity. The company announced today that during productronica 2023 in Hall A4, Booth 246/3, visitors can experience M.O.L.E. EV6 first-hand, see a preview of soon-to-be-launched profilers, demo OvenSENTINEL® reflow monitoring technology, and learn more about the scalable RIDER soldering equipment verification portfolio.

“Maximum productivity and expansive data are the keys to process efficiency and product quality,” says ECD Electronics Division Manager, Mark Waterman. “ECD’s objective from its founding has been to deliver on these elements through robust measurement, monitoring, and analysis technologies. As the market has evolved and data acquisition and presentation made more seamless, our product line has followed suit. The ability to view and act on information immediately through M.O.L.E. EV6’s touchscreen visibility and OvenSENTINEL’s real-time reflow monitoring are two examples that have demonstrated measurable improvements in yield, quality, and cost-efficiency. For ECD, this is a journey, and we continue to add features to existing technologies and bring new solutions to the industry. We’re excited to showcase many of these at productronica 2023.”

Expanding on M.O.L.E. EV6’s feature set, ECD has integrated Bluetooth wireless technology to enable remote data acquisition of real-time profile conditions through its M.A.P. software. This Bluetooth capability, ECD’s scalable WaveRIDER® NL 2, OvenRIDER® NL 2+, and SelectiveRIDER® sensor products, and the company’s OvenSENTINEL reflow soldering continuous monitoring software will be demonstrated throughout the four-day productronica event.

With the M.O.L.E. EV platform exceeding expectations, ECD has accelerated its planned rollout of additions to the EV-generation profiler portfolio. Currently in development, new high channel count tools will offer more flexibility for the demanding process needs of each customer and address market-specific requirements. Visitors to ECD’s productronica exhibit can see a preview of the new technologies, which are set to be commercialized in early 2024.

“Particularly for high-value, high-reliability PCBs destined for mission-critical applications like automotive, aerospace, alternative energy, and high-performance computing, expanded thermal profile data points are required to ensure compliant, fail-safe manufacturing,” says Waterman. “Our newest EV-series M.O.L.E.s will offer this capability, and we look forward to sharing them with the market soon!”

To schedule time with ECD’s technology team at productronica 2023, email mike.hayward@ecd.com. Learn more about ECD’s electronic process control technologies by visiting www.ecd.com.

Except as otherwise noted, all marks used herewith are trademarks and/or registered trademarks of ECD and/or its affiliates in the US and elsewhere

About ECD

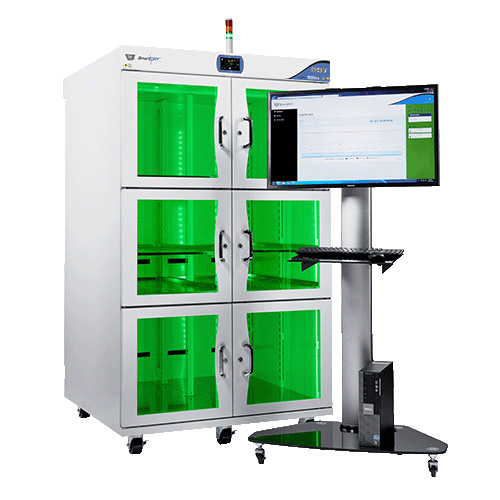

Founded in 1964, ECD is recognized worldwide for its leadership and expertise in thermal monitoring and analysis technology and, more recently, for its development of intelligent dry storage systems. Based in Milwaukie, Oregon, the company is a pioneer in the design, development, and manufacture of advanced in-transit thermal profiling systems and software used to monitor and analyze process temperatures in various industries including electronics, solar and baking, among others. Well-known for its data-rich software expertise and robust hardware functionality, ECD leads the industry for innovative measurement and safeguarding systems. For more information on ECD and its products, visit www.ecd.com.

Media Contact:

Laura Sims

Sims Communications, Inc.

(o) 770-829-4757

(m) 404-661-0348

laura@simscomm.com