Want to be notified of news like this? Become an ECD Insider and be in the know first.

ECD Expands Technical Service Team to Support Growing Customer Base

New Senior Product Support Technician Upholds Company’s Personalized, Responsive Approach to Customer Service.

June 20, 2024 – ECD today announced that it has increased its customer support staff to ensure its continued, award-winning legacy of timely, personalized customer assistance. Along with its product innovation leadership, ECD has built a solid reputation based on trusted, high-quality, responsive service. The company’s latest hire, Rob Bishop, has joined the team as a Senior Product Support Technician to uphold this commitment.

Bishop brings broad experience to ECD, having previously held positions in equipment maintenance, personnel and customer technical training, field service support, and technical documentation writing. Over the last twenty years, he has worked primarily in the semiconductor manufacturing sector and, most recently, was a training project manager at Lam Research. Rob is a self-described solution-seeker who is technically skilled, innately curious, and passionate about helping people.

“By nature, I am a fixer and a technology nerd,” shares Bishop. “Ensuring proper calibration so our products are at peak performance is critical to our brand reputation and I’m proud to be part of that. I also enjoy meeting and learning from people of all different backgrounds and cultures, which this job allows me to do. Having come from larger organizations, working in a collaborative, tight-knit company like ECD where my contributions are palpable is refreshing. I look forward to learning, growing, and helping our customers succeed.”

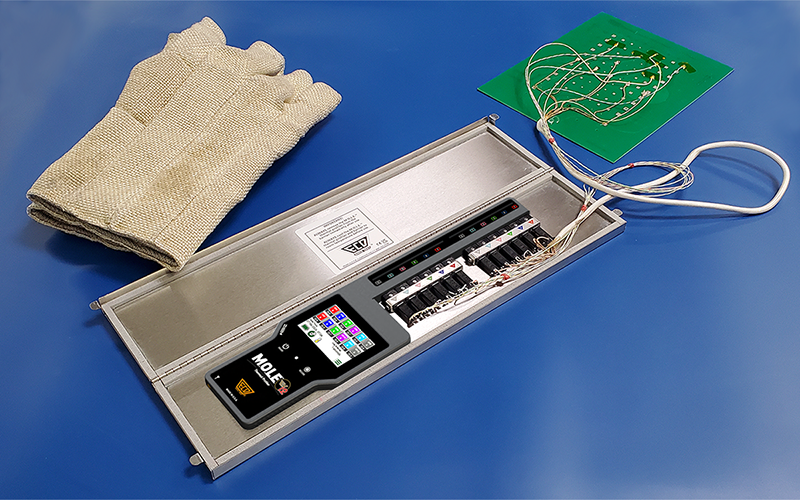

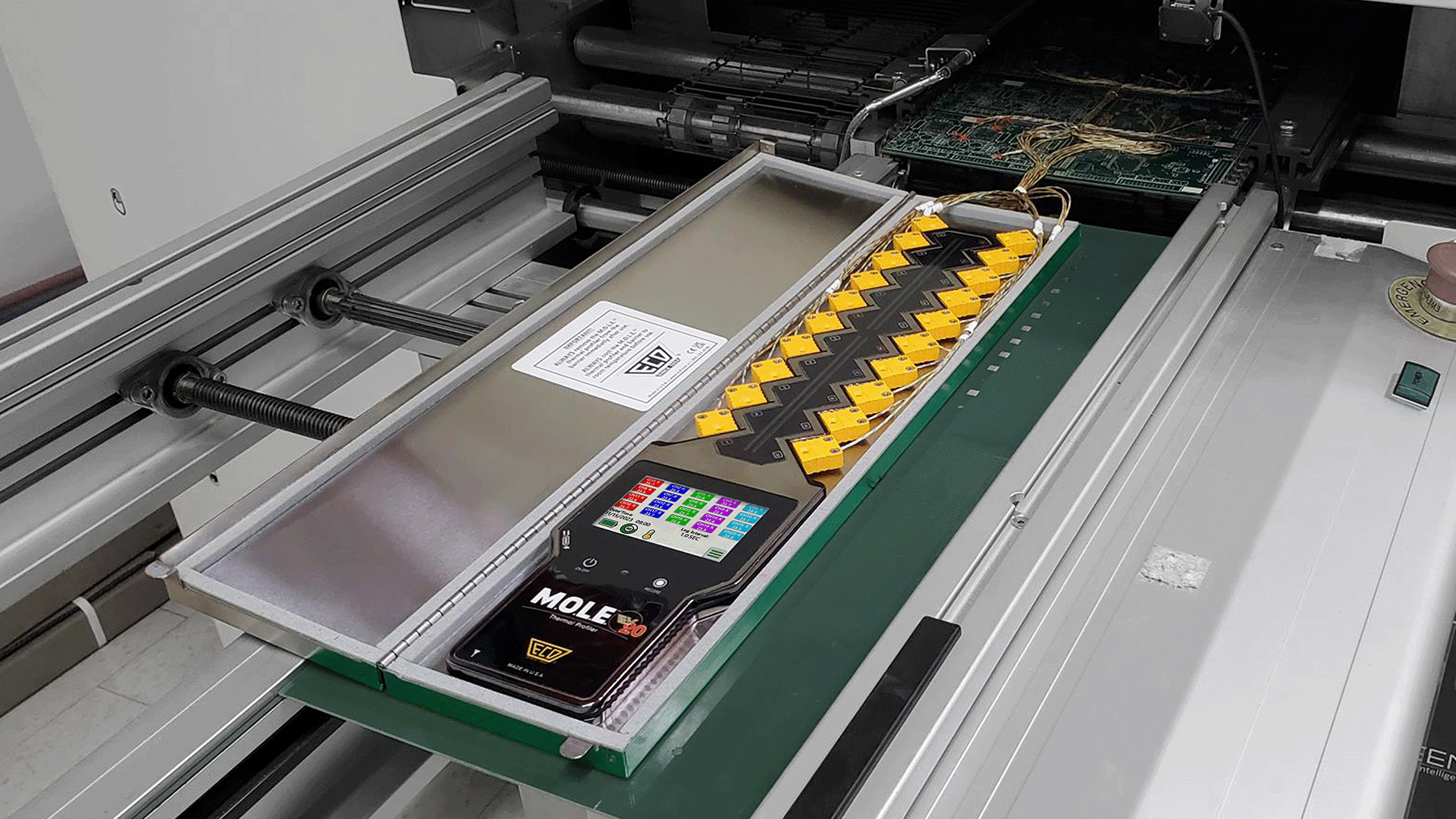

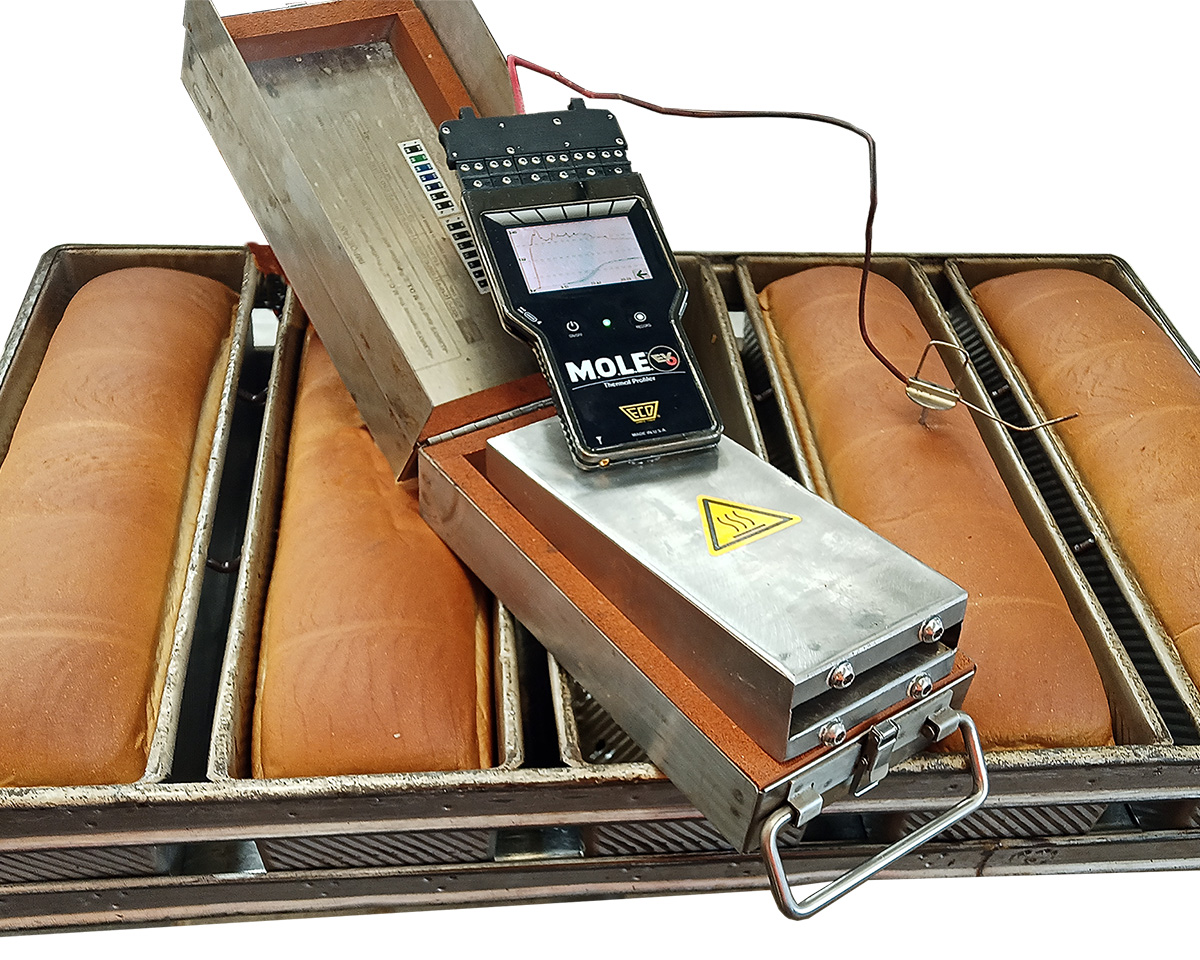

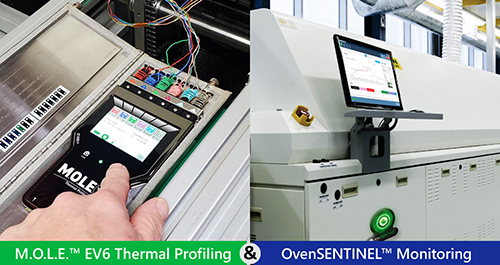

ECD’s thermal profiler, machine quality management, product sensor, and humidity-controlled storage cabinet portfolios have enjoyed a steady growth trajectory. Most notably, the company’s recently-introduced M.O.L.E.™ EV-series touchscreen thermal profilers — with three models now commercialized – have exceeded sales expectations. The industry uptake necessitated additional resources for routine scheduled device calibration, process troubleshooting, and technical guidance.

ECD President Tara Fischer says that customer support is the solid foundation on which ECD is built and is not something the company will outsource; adding internal staff was essential. “We have developed incredibly impactful process control technologies, and enabling our customers to get the most out of our products’ capabilities is our top priority,” she explains. “Customer support takes technical knowledge, yes, but also a calm demeanor, respectful communication, and a willingness to do whatever it takes to satisfy the customer. Rob has demonstrated all these characteristics, and we — and ECD customers – are grateful he is part of our growing team.”

Bishop holds a Bachelor of Applied Science in Automated Manufacturing Technology from ITT Technical Institute in Portland, OR. He is based in ECD’s Milwaukie, OR headquarters.

Except as otherwise noted, all marks used herewith are trademarks and/or registered trademarks of ECD and/or its affiliates in the US and elsewhere

About ECD

Founded in 1964, ECD is recognized worldwide for its leadership and expertise in thermal monitoring and analysis technology and, more recently, for its development of intelligent dry storage systems. Based in Milwaukie, Oregon, the company is a pioneer in the design, development, and manufacture of advanced in-transit thermal profiling systems and software used to monitor and analyze process temperatures in various industries including electronics, solar and baking, among others. Well-known for its data-rich software expertise and robust hardware functionality, ECD leads the industry for innovative measurement and safeguarding systems. For more information on ECD and its products, visit www.ecd.com.

Media Contact:

Laura Sims

Sims Communications, Inc.

(o) 770-829-4757

(m) 404-661-0348

laura@simscomm.com