Want to be notified of information like this? Become an ECD Insider and be in the know first.

ECD Adds Vapor Phase Reflow Solution, Expands Solder Process Capability

Addition of Vapor Phase Barrier Delivers Scalable Profiling Portfolio for Every Soldering Process – Reflow, Wave, Vapor Phase, and Selective.

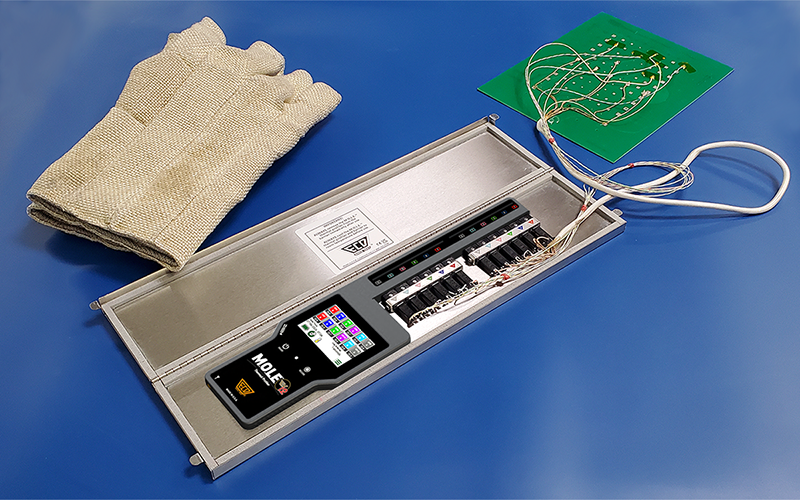

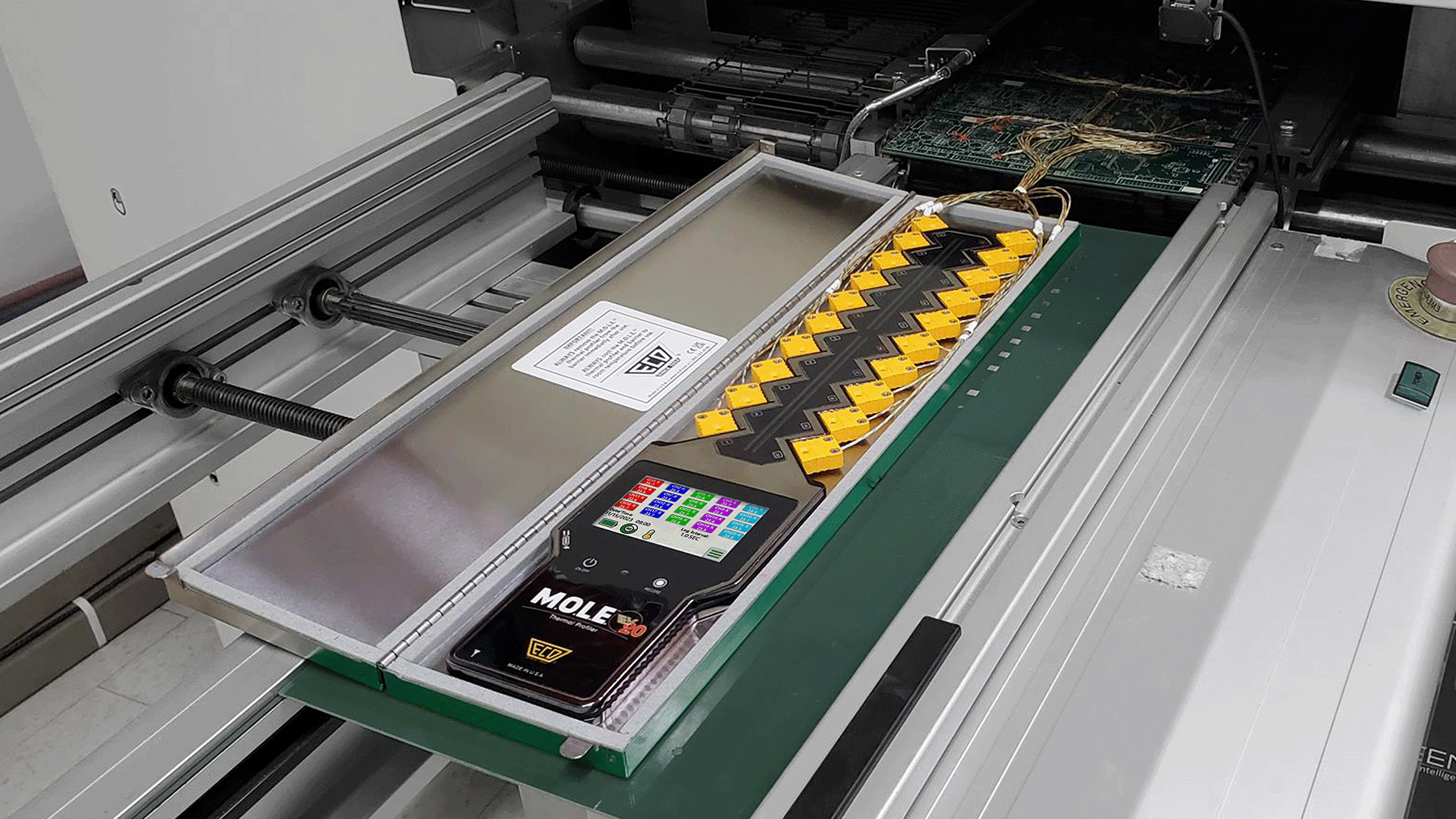

February 12, 2025 – ECD today announced the addition of a rugged vapor phase reflow soldering barrier to its product portfolio. The M-VP™ will debut at ECD Booth # 2705 at the IPC APEX EXPO event next month. Designed for use with any ECD six-channel M.O.L.E.® thermal profiler, including the award-winning touchscreen M.O.L.E. EV6, M-VP enables profile measurement of the harshest vapor phase environments. The M-VP barrier joins ECD’s machine quality management pallets OvenRIDER® NL 2+, WaveRIDER® NL 2, and SelectiveRIDER®, completing the line-up of modular process control solutions for wave, reflow, selective, and vapor phase soldering.

Suitable for use in both batch and in-line vapor phase reflow soldering equipment, with or without vacuum, M-VP provides the extreme protection needed to ensure data accuracy and prevent device damage. The barrier is compatible with the high-temperature environment (up to 260° C) of condensation reflow, is impervious to vapor and moisture, and resistant to damage or deformation during vacuum stages.

“When engineering ECD’s vapor phase barrier, the objective was to go beyond conventional solutions in all aspects,” explains ECD Electronics Division Manager Mark Waterman. “That included everything from the barrier material properties to operator ease-of-use to fail-safe structural integrity even under vacuum pressure. We have delivered these attributes and more.”

ECD’s M-VP sealed barrier sets a new benchmark for vapor phase solder profiling, ensuring exceptional data accuracy, profiler protection, and barrier longevity with an expansive feature set, including:

- Rugged construction

- Strong, high-performance, watertight thermoplastic material

- Degradation- and contamination-resistant insulating material

- Sleek, hydrophobic design avoids accumulation and loss of costly Galden®

- Shock and drop resistant

- Withstands harsh environments, no deformation under vacuum

- Operator friendly

- Easy open/close clips with no screws

- Enables use of time-saving M.O.L.E. EV6 touchscreen profiler for lineside data analysis

- Easy to clean

- Optimized wireless communication with Bluetooth capability

- Process adaptable

- Withstands temperatures up to 260° C (peak)

- Compatible with other electronics assembly processes, including traditional wave and convection reflow soldering, PCB cleaning, and formic acid no flux reflow

- Food-safe material extends potential use to many applications

Mark Waterman explains that ECD’s new M-VP barrier overcomes the challenges of other vapor phase profiling approaches while rounding out the portfolio to allow a single platform for all soldering processes.

“The rugged, reliable protection and process flexibility M-VP affords are significant advantages for manufacturers,” says Waterman. “With a six-channel M.O.L.E. thermal profiler, assembly professionals can accurately profile any soldering process and enjoy the benefits of standardized software and hardware. It certainly simplifies operations and elevates reliability.”

ECD’s M-VP vapor phase barrier is available for pre-order in mid-March, with the first units shipping in April.

Except as otherwise noted, all marks used herewith are trademarks and/or registered trademarks of ECD and/or its affiliates in the US and elsewhere

About ECD

Founded in 1964, ECD is recognized worldwide for its leadership and expertise in thermal monitoring and analysis technology and, more recently, for its development of intelligent dry storage systems. Based in Milwaukie, Oregon, the company is a pioneer in the design, development, and manufacture of advanced in-transit thermal profiling systems and software used to monitor and analyze process temperatures in various industries including electronics, solar and baking, among others. Well-known for its data-rich software expertise and robust hardware functionality, ECD leads the industry for innovative measurement and safeguarding systems. For more information on ECD and its products, visit www.ecd.com.

Media Contact:

Laura Sims

Sims Communications, Inc.

(o) 770-829-4757

(m) 404-661-0348

laura@simscomm.com